Food industry

Food industry

Innovative feet for the food industry

VERMAY considers food processing machinery and equipment as a specific branch of general machinery and equipment. In our society, the processing of food products has to meet the highest standards, and rightly so, and VERMAY is of course happy to do so. How are the VERMAY machine bases used in this field and what are the special features of them? The processing systems are used in the food industry for the production of liquid to pasty products. The machine bases must ensure a very stable and secure stand as well as a very finely adjustable height compensation in order to guarantee an ideal product flow depending on the surface, e.g. under system components such as the vacuum unit, auxiliary container or control cabinet. Of course, strict cleanliness and hygiene requirements apply in food production. For this reason, our machine feet are almost exclusively made of stainless steel.

However, hygiene requirements have become even stricter, which means that machines and process systems used in the food industry must meet the standards of “hygienic design”, i.e. the hygienic design of machines, systems and components used in the food sector, certified by independent institutes. One of the most important criteria is to avoid the formation of bacteria by using seamless components and to prevent the contamination of food by decomposing machine parts, such as seals.

VERMAY has once again risen to this great challenge and is proud to present its latest development, the certified ZH-TG hygienic foot (see the text on this page)!

Mittlerweile sind jedoch die hygienischen Anforderung weiter gestiegen, wonach Maschinen und Prozessanlagen in der Lebensmittel verarbeitenden Indstrie den Standards des sog. „Hygienic Design“ entsprechen müssen – also die hygienegerechte Gestaltung von Maschinen, Anlagen und Komponenten im Nahrungsmittelbereich mit entsprechender Zertifizierung durch unabhängige Institute. Wichtiges Kriterium ist hierbei die Vermeidung von Bakterienbildung durch spaltfreie Komponenten und die Verhinderung einer Kontamination der Lebensmittel mit sich zersetzenden Maschinenteilen, wie beispielsweise Dichtungen.

VERMAY hat sich dieser großen Herausforderung erneut angenommen und präsentiert als neueste Entwicklung erstmals den Zertifizierten Hygienefuß ZH-TG (s. Text dort)!

application examples

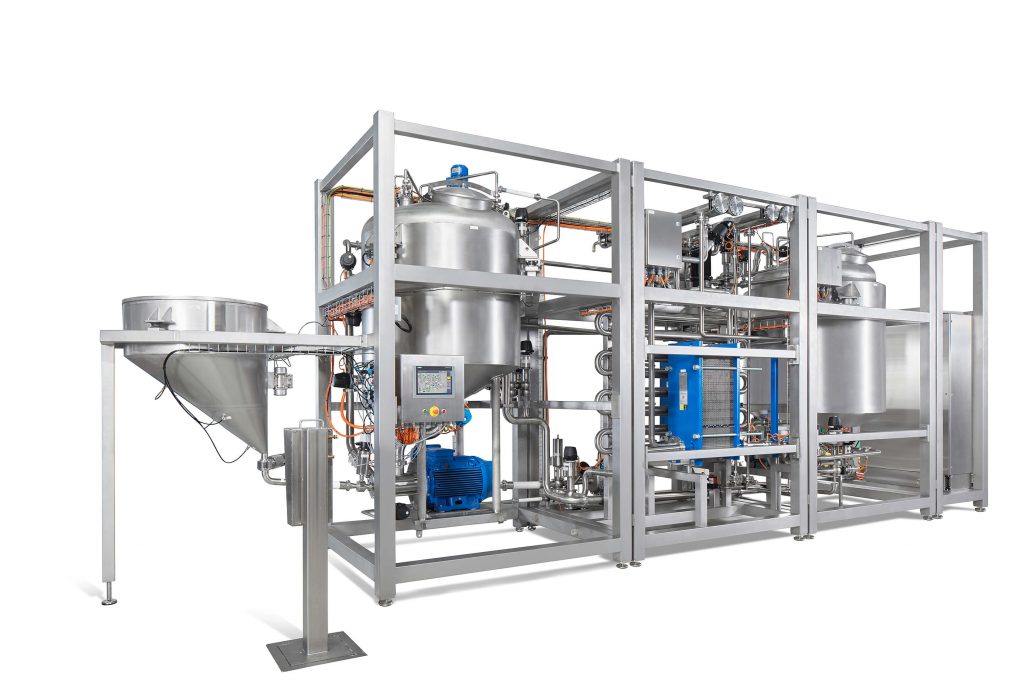

AZO Liquids GmbH

AZO LIQUIDS GmbH in Neuenburg am Rhein, Germany, has been purchasing machine feet from Vermay in Pulheim, near Cologne, Germany, for many years. For our core business – the process systems – the machine bases have always been an important element. Our process systems are used for the production of liquid to pasty products by our customers in the food, pharmaceutical and cosmetic industries. A secure base on the floor of the production hall is essential for our process systems. Otherwise, safe working conditions cannot be guaranteed. Even under system components such as the vacuum unit, supply tank or control cabinet, Vermay machine feet are used. In addition to stable floor mounting, Vermay machine feet can be used to adjust the height of process systems. This allows the systems to be optimally aligned depending on the surface to be processed to ensure ideal product flow. We at AZO LIQUIDS have been very satisfied with the products from Vermay. The key to this satisfaction is not only reliable supplier loyalty, but also consistent product quality.